BLENDING, FORMULATION AND ADVISORY

With the increasing prevalence of low sulfur fuels, biofuels and other fuel types, blending different fuels can be challenging. V-TIC Services can help! Using our deep industry knowledge and cutting edge technology, V-TIC Services can help guide your blending process to ensure that you meet standards and specification without resorting to expensive residue desulfurizers or hydrocrackers.

The typical concern is the incompatibility issue between the supplied highly paraffinic products and the blending materials that contain asphaltene. By blending the highly paraffinic oil with highly aromatic residual fuels, the asphaltenes (the heaviest fraction of the fuel) will agglomerate and precipitate in tanks, separators, and filters creating huge problems. This is the reason why many owners choose not to buy those fuels.

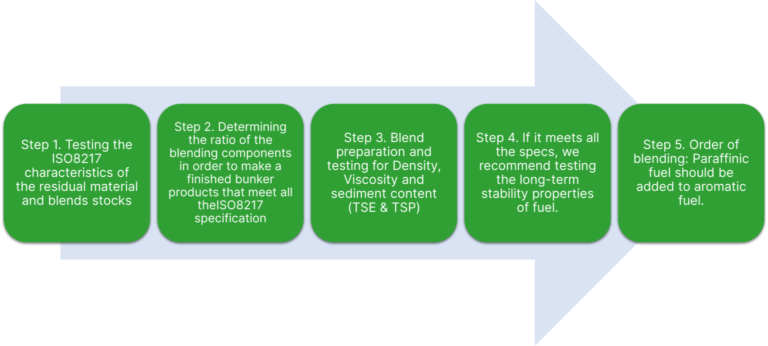

The below chart shows the detailed blending procedure that VTIC follows in order to ensure that the final blends can stay stable over time and meet ISO8217 specifications.

What should be the order of blending?

Paraffinic fuel should be added to aromatic fuel in order to avoid asphaltene sludging. The low aromaticity of the paraffinic base fuel will be disturbed if an aromatic fuel is poured into a paraffinic tank, which increases the likelihood of asphaltene sludging.

V-TIC CAN HELP ANALYZE YOUR FUEL

SARA ANALYSIS

Saturates, Aromatics, Resins and Asphaltines

PNA ANALYSIS

Paraffin, Naphthene, Aromatic + Density/Viscosity