FUEL QUANTITY INSPECTION

WHAT IS FUEL QUANTITY INSPECTION?

Fuel Quantity Inspection refers to the process of measuring the amount of fuel in a storage tank, usually performed to verify the accuracy of the fuel gauge or meter and to ensure compliance with fuel inventory regulations. The inspection involves the use of specialized equipment and techniques to determine the volume of fuel present in the tank and to identify any discrepancies between the actual and indicated amounts.

PROBLEMS DURING FUEL QUANTITY INSPECTION

During fuel quantity inspection, there can be several problems that arise, including:

The fuel gauge or meter may give incorrect readings due to technical issues or malfunctions

Improper storage conditions can lead to fuel contamination or evaporation, affecting the accuracy of the inspection

If the fuel delivery and usage records are not accurately maintained, it can lead to discrepancies during the inspection

Calculation errors or measurement mistakes made during the inspection process can result in inaccurate results

The inspection process may encounter technical difficulties, such as difficulties in accessing the fuel storage tank, or difficulties in obtaining an accurate reading due to the presence of obstacles or sludge

These problems can result in discrepancies between the actual and indicated fuel quantity, and can have significant financial implications for the fuel owner or operator.

VOLUME CORRECTION FACTOR (VCF)

HOW IS THE VOLUME CORRECTION FACTOR CALCULATED?

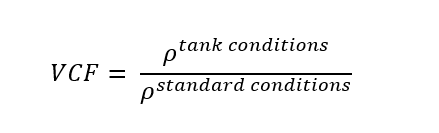

The volume correction factor (VCF) is calculated to account for the variations in fuel density due to temperature, pressure, and other physical factors. The VCF is used to correct the volume of fuel measured in a storage tank to its actual volume at a standard temperature and pressure.

The VCF is usually calculated using the following formula:

The density of the fuel at tank conditions is usually measured using a fuel density meter or calculated based on the temperature and pressure readings. The density of the fuel at standard conditions is usually taken from a fuel reference table or manual. It is important to note that the VCF calculation is specific to the type of fuel being measured and the method used for measurement. Accurate calculation of the VCF is critical for obtaining accurate results during fuel quantity inspections.

WHAT TABLES ARE USED FOR VOLUME CORRECTION FACTOR CALCULATION?

ASTM TABLES

The American Society for Testing and Materials (ASTM) publishes reference tables for the density of various fuels at standard temperature and pressure

MANUFACTURER'S MANUAL

Some fuel manufacturers provide reference manuals that contain information on the density of their fuel at standard conditions

PETROLEUM MEASUREMENT TABLES

The International Organization for Standardization (ISO) publishes Petroleum Measurement Tables that provide data on the density of various fuels at standard conditions

STANDARDIZED TABLES

There are also standardized tables, such as the Table 54B or Table 6B, that provide the density of various fuels at standard conditions and are widely used in the fuel industry

These tables and manuals provide the density of fuel at standard conditions, which is then used in the calculation of the VCF to correct the volume of fuel measured in the tank. Accurate calculation of the VCF requires the use of the correct reference table or manual that corresponds to the type of fuel being measured.

WHAT MISTAKES HAPPEN DURING VCF CALCULATION?

During the calculation of the volume correction factor (VCF), several mistakes can occur, some of which are:

INCORRECT DENSITY DATA

If the incorrect reference table or manual is used, it can result in an incorrect calculation of the fuel density at standard conditions and the VCF

IMPROPER MEASUREMENT

Incorrect temperature and pressure readings can result in an inaccurate calculation of the fuel density at tank conditions

CALCULATION ERRORS

Mistakes made during the calculation of the VCF, such as incorrect use of formulas or data, can result in inaccurate results

INADEQUATE DOCUMENTATION

Lack of proper documentation or records of the temperature and pressure readings or the reference tables or manual used can lead to errors during the calculation.

HUMAN ERROR

Incorrect data entry, incorrect use of units or conversion factors, or other human errors can also result in mistakes during the calculation of the VCF.

These mistakes can result in significant discrepancies between the actual and indicated fuel quantity, and can have financial implications for the fuel owner or operator. It is important to follow proper procedures and to verify the accuracy of the calculations to minimize the risk of errors during the calculation of the VCF.

CHOOSING THE RIGHT PARTNER

When choosing an inspection company for loss control, it’s important to consider several factors to ensure that the company can meet your needs:

EXPERIENCE & EXPERTISE

A reputable inspection company has experienced technicians who are trained and equipped with the knowledge and skills necessary to perform accurate fuel quantity inspections

EQUIPMENT & TECHNOLOGY

A good inspection company uses the latest and most accurate equipment for measuring the volume of fuel in a storage tank

REPUTATION

Look for a company with a good reputation in the industry, and ask for references from other organizations that have used their services

REGULATORY COMPLIANCE

A good inspection company is knowledgeable about fuel inventory regulations and ensures that their services are in compliance with these regulations

ACCURACY

Accuracy is crucial for ensuring compliance with fuel inventory regulations and for avoiding financial losses due to discrepancies between the actual and indicated fuel quantities

COMMUNICATION

Consider the company's communication and reporting capabilities, including the level of detail they provide in their reports, and their ability to clearly explain their findings and recommendations

Choosing the right inspection company is important to ensure that the fuel quantity inspection process is performed accurately and efficiently, and to minimize the risk of errors and discrepancies in the results.

V-TIC Services is proud to be a certified member of the TIC Council, abiding by the TIC Council Compliance Code. We employ IFIA certified Inspectors.